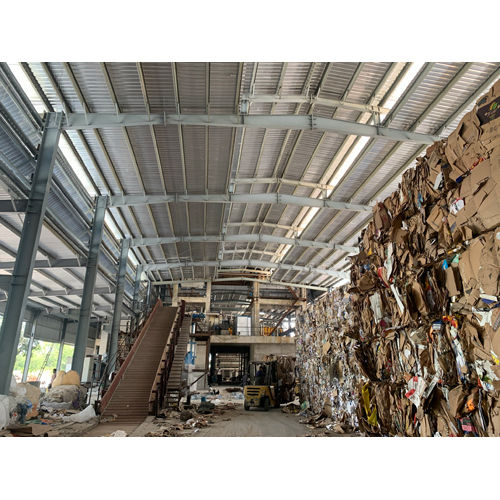

Pre-engineered building structures, also known as PEB structures, are modern-day construction solutions that offer cost-effective and efficient solutions for a wide range of industrial, commercial, and residential projects. These structures are pre-fabricated and manufactured off-site, then transported and assembled at the construction site. Considering their importance and ever-increasing demand, we, Utkarasha Enterprises, stepped into the market with a wide variety of PEB Factory Buildings, PEB Godown Sheds, Pre-Engineered Structures, Pre-Fabricated Structures, and more. We are established as a manufacturer and supplier. All the aforementioned products are designed and engineered using state-of-the-art technology and advanced manufacturing techniques at our production unit, ensuring consistent quality and precision.

All the PEB structures are customizable and can be tailored to meet the specific needs of customers. Our team of diligent professionals sits with the customers and understands their specific requirements. Accordingly, design and develop the products, providing complete satisfaction to the customers. For us, 100% customer satisfaction acts as our biggest growth driver. Since, the beginning, we have focused on keeping our customers happy and satisfied with our products and services.

All the PEB structures are customizable and can be tailored to meet the specific needs of customers. Our team of diligent professionals sits with the customers and understands their specific requirements. Accordingly, design and develop the products, providing complete satisfaction to the customers. For us, 100% customer satisfaction acts as our biggest growth driver. Since, the beginning, we have focused on keeping our customers happy and satisfied with our products and services.